Heat Treatment Salt

Explore

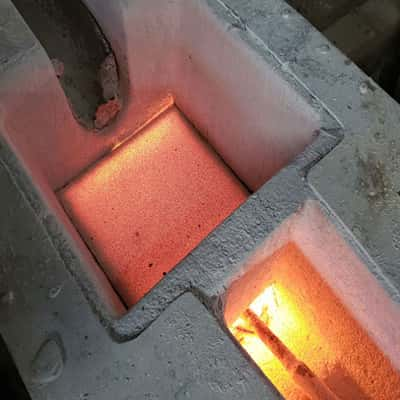

Ceramic Foam Filter

Home Ceramic Foam Filter

Dhatukarm’s Ceramic Foam Filters are engineered to deliver exceptional molten metal filtration in foundry and casting applications. These advanced filters are designed to remove non-metallic impurities, inclusions, and slag from molten metals, significantly improving the quality, integrity, and finish of the final cast products. Made from high-purity ceramic materials, they offer superior thermal stability and mechanical strength, making them ideal for both ferrous and non-ferrous metal casting. With a controlled pore structure, these filters ensure a smooth and laminar metal flow, reducing turbulence and preventing casting defects. They are available in a wide range of sizes, thicknesses, and porosities to meet the specific requirements of aluminum, steel, copper, and iron casting processes. Dhatukarm’s commitment to consistent performance and customized solutions makes these ceramic foam filters a trusted choice across industries such as automotive, aerospace, and heavy engineering.In modern casting operations, maintaining metal purity is critical, and Dhatukarm’s Ceramic Foam Filters play a vital role in achieving this goal. Their open-cell, three-dimensional interconnected structure allows for excellent filtration efficiency without significantly impeding the flow of molten metal.

Enquire NowDhatukarm offers high-performance Ceramic Foam Filters designed for efficient filtration of molten metal during casting processes. These filters effectively remove non-metallic inclusions and trap slag and oxides, ensuring cleaner metal flow and improved casting quality across ferrous and non-ferrous alloys.

Available in various dimensions, thicknesses, and pore sizes (PPI) to meet specific foundry needs. We also offer custom solutions for different metals and flow rates.

Company: Dhatukarm

Email: mukeshjaindhatukarm1@yahoo.com

Phone: +91-9212023514, 011-22175044