Heat Treatment Salt

Explore

Modifier Cover Fluxes

Home Modifier Cover Fluxes

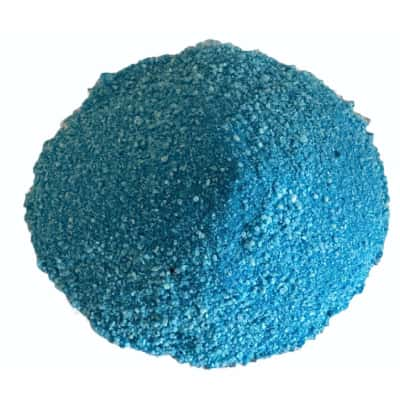

Modifier Cover Fluxes are multifunctional additives used extensively in non-ferrous metallurgy to refine the melt, prevent oxidation, and optimize casting results. Specifically designed for aluminum and its alloys, these fluxes cover the molten surface to act as a barrier against air, reduce dross formation, and assist in modifying the grain structure during solidification. This results in improved strength, ductility, and surface finish of the final cast products. Dhatukarm’s Modifier Cover Fluxes are known for their low melting point, controlled reaction rate, and minimal fume generation. Whether used in ladle refining or furnace melting, they help maintain a clean melt, increase metal recovery, and reduce porosity in castings. By integrating Dhatukarm's fluxes into your process, you gain consistent casting outcomes, better operational control, and superior metallurgical quality—all backed by decades of field-proven experience and innovation.

Enquire NowModifier Cover Fluxes are specialized fluxes used during the melting and refining of non-ferrous metals, particularly aluminum and its alloys. These fluxes improve melt cleanliness, modify grain structure, and reduce inclusions, ensuring better casting quality and mechanical properties.

Dhatukarm’s Modifier Cover Fluxes are formulated to perform multiple roles—covering the molten metal surface, reducing oxidation, improving metal fluidity, and modifying the structure for enhanced strength and finish. They help remove dross, prevent hydrogen absorption, and reduce metal loss due to oxidation, making them essential for aluminum foundries and extrusion operations.

Company: Dhatukarm

Email: mukeshjaindhatukarm1@yahoo.com

Phone: +91-9212023514, 011-22175044