Crafting Metallurgical Excellence Since 1989

Dhatukarm is a renowned name in the Heat Treatment Industries as a supplier and manufacturer of all kinds of Heat Treatment salts i.e Hardening, Carburizing Tempering Salts and Liquid Nitriding Salts for Extrusion Dies.The company also manufacture and install Zero Leakage Ammonia Gas Nitriding Plant, Liquid Nitriding Plant and Heat Treatment Plant with world's latest best technology for tools and Aluminium Extrusion Dies at lowest price under the guidance and technology developed by I.I.T Metallurgical Engineer having 35 Years of Experience in the field of Heat Treatment. The company has all in house production capacity to meet the requirement of customers and endeavour to manufacture quality and cost reliable products. The company has a high standard of quality & is equipped with state of art facilities. Dhatukarm believes in achieving total customer satisfaction, professional approach for continual technological upgradation & consistency in quality without compromise. Its first aim is to produce high-quality products at most competitive prices.

Read MoreFrom heat treatment salts to graphite products — we offer metallurgical excellence that delivers results.

With a legacy dating back to 1989, Dhatukarm brings unmatched knowledge and reliability in metallurgical product manufacturing. Our long-standing expertise ensures consistent quality and customer satisfaction.

From heat treatment salts and nitriding salts to graphite products, degassers, and fluxes — we offer a complete portfolio to meet diverse metallurgical and foundry needs under one trusted name.

Our products are engineered for efficiency, durability, and optimal process outcomes. Whether it's for casting, refining, or heat treatment, Dhatukarm delivers solutions that perform.

Every product undergoes rigorous quality testing to ensure it meets exacting standards. With precise compositions and reliable chemical behavior, we guarantee product consistency every time.

We don’t just supply — we solve. Dhatukarm offers customized formulations and expert support to help clients overcome specific metallurgical challenges and improve process efficiency.

Our robust distribution network ensures timely and safe delivery across India. We understand the value of time in industrial operations — and we never compromise on logistics.

Precision-Engineered Solutions for Metallurgical Excellence.

Delivering High-Performance Solutions for Complex Metallurgical Processes.

With decades of hands-on experience, Dhatukarm has mastered the art and science of Salt Bath Heat Treatment. Our team specializes in designing, developing, and installing highly efficient salt bath systems tailored to meet a wide range of industrial applications. Whether it's carburizing, hardening, tempering, or nitriding, we ensure optimized thermal consistency, energy efficiency, and precise metallurgical results.

From consultation to commissioning, we deliver end-to-end solutions with a deep focus on operational safety, longevity, and customization. Our systems are trusted across industries such as automotive, aerospace, tool manufacturing, and medical components. Leveraging cutting-edge technology and an in-depth understanding of metallurgy, Dhatukarm integrates automation, precise temperature control, and chemical balance monitoring into every salt bath installation. Our systems are engineered to minimize downtime, reduce salt consumption, and maximize throughput — ensuring sustainable and scalable operations for our clients. We take pride in offering fully customized solutions, including layout design, selection of salts, heating sources, and safety controls based on the specific process needs. Our in-house R&D team continuously innovates to meet evolving industrial standards and environmental compliance.

Molten salts are usually used as a medium in Carburizing, Hardening, Annealing, Preheating, Tempering, Martempering, Austempering etc. Molten salt baths of various composition are available to cover the temperature range 150-1350`c. Since the work is surrounded by salt, heating is uniform, distortion is less and part can be machined before heat treatment. Treated parts have a clean, bright, scale free finish and decarburization can be completely eliminated.

| Processes | Salts Name | Working Range (°C) | I.C.I. Equivalents |

|---|---|---|---|

| Hardening Salt | H.Q. 970 | 970–1350 °C | HS 970 |

| H.Q. 871 | 980–1350 °C | HS 971 | |

| H.Q. 950 | 720–1050 °C | For Extrusion Die | |

| H.Q. 830 | 830–1100 °C | HT 830 | |

| H.Q. 660 | 660–900 °C | NC 660 | |

| H.Q. 720 | 720–900 °C | WS 720 | |

| H.Q. 650 | 650–900 °C | AS 650 | |

| Quenching Salt | H.Q. 540 | 540–700 °C | QS 540 |

| H.Q. 530 | 500–700 °C | For Extrusion Die | |

| H.Q. 495 | 495–700 °C | QS 495 | |

| Tempering Salt | H.Q. 150 | 160–550 °C | TS 150 |

| H.Q. 220 | 230–550 °C | TS 220 | |

| H.Q. 330 | 330–535 °C | TS 330 | |

| Heat Transfer Salt | H.Q. 155 | 155–540 °C | TR 155 |

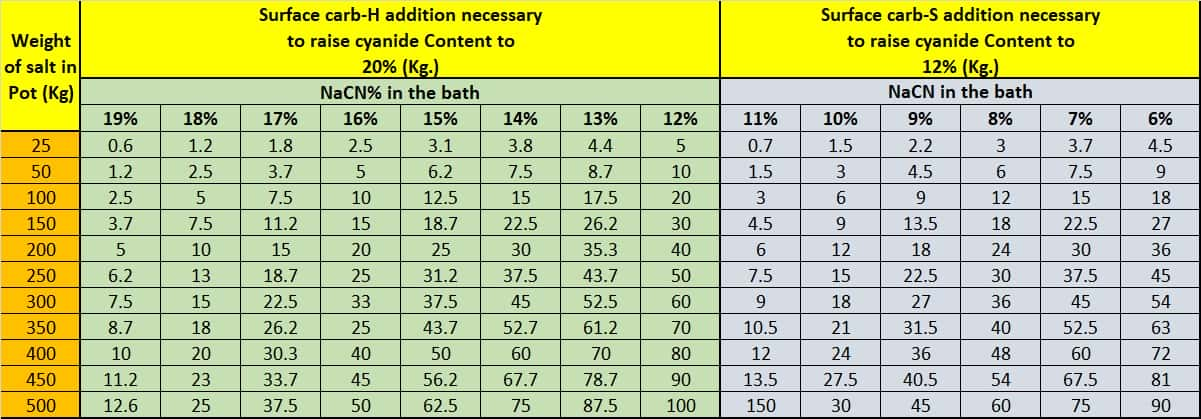

| Carburizing Salt | Surface carb-H | 760–925 °C | Rapi Carb-H |

| Surface carb-S | 800–950 °C | Rapi Carb-S | |

| Regenerator | H.Q. Regenerator | Regenerator-A | |

| H.Q. Regenerator Granules | |||

| H.Q. Regenerator 970 | |||

| Economiser | H.Q. Economiser | Economiser | |

| H.Q. Ash Free Economiser | |||

| H.Q. Economiser Flake | |||

| Liquid Nitriding Salt | H.Q. 4 (Base Salt) | 560–580 °C | CR 4 (TF-1) |

| H.Q. 2 (Regenerator Salt) | CR 2 | ||

| Protective | H.Q. Protective | Espone K | |

| H.Q. Protective - 02 | Espone KS | ||

| Blackening Salt | Auto Black - 01 | 140–145 °C |

Feel Free To Share Your Query...